Everything you ever wanted to know about glycol plumbing

How you install your chiller is just as important as the chiller itself. The layout and design of a system can make all the difference. We have been installing systems since 1972.

Always plan for expansion, don't plumb yourself into a corner, make sure you can add to the system and make repairs if needed.

Glycol plumbing is what is called “process plumbing”. It goes from the chiller and back to the chiller. Generally it is not hooked to city water and you definitely don’t want it hooked to the drainage system. Glycol is not cheap.

Most of all, plan your layout and size everything to work for today and tomorrow. Tanktemp offers design and engineering services as well as full installation and maintenance.

Here is what everyone else won’t tell you.

What is glycol?

In short, it is antifreeze. Propylene glycol is what breweries and wineries need. You are looking for food grade USP. Glycol comes in different pre-mixed percentages, all are fine to use in your system, but you need to make sure you mix it correctly. You will want to use a refractometer and set the glycol to 22-24+ Brix for your 28F set point; some chiller manufacturers require a heavier mixture. Please refer to our glycol chart below for your required glycol temperature setting and corresponding glycol Brix strength. Keep in mind that the actual temperature inside the heat exchanger will be 15℉ colder than your set temperature, this is why the Brix needs to be concentrated enough to prevent freezing in the heat exchanger. If you are using 99-100% glycol ( what we recommend ) you are looking for a ⅓ glycol ⅔ water mixture. Water is a better thermal conductor than glycol and the high viscosity of glycol is hard on the pumps in your unit if the mixture is too concentrated.

The basics of plumbing

- Always flow into the bottom of your tank jacket, and out the top.

- This helps purge the system of air, will keep the system primed, and reduce cavitation of the pump(s).

- Place the solenoid controls valves on the tank inlet(s).

- This setup will control the flow going into the tank.

- Use a closed system.

- What this means is that you will have a supply line and a return line running through your facility that do not connect at the end. The supply line runs from the chiller into your facility and connects to the supply side of any tanks or equipment, then it stops. There will be a separate return line that runs from the chiller into your facility connecting to the return side of tanks or equipment and will also stop. If you connect these lines together, forming an open loop system, the glycol will take the path of least resistance and only flow from the chiller and back to the chiller in the open loop, not into any tank jackets or equipment.

- Do not vent the lines ( Most common plumbing error ).

- The vent will allow the glycol from the plumbing and the jackets to drain back into the chillers reservoir and over fill it.

- Brace your plumbing well. Every 6’ is recommended to support the weight of the product.

- Plumbing and glycol are heavy and as you connect and disconnect your hoses you will need to press the hoses on to the plumbing.

- Use ball valves to create zones so you can expand and repair your system without completely shutting down.

- Something, at some point will break. Set the system up so repairs can be made and maintenance can be done without having to shut the whole system down or drain it.

- The less bends the better.

- Every bend in a system causes flow loss and turbulence in the system. Bends in the system are not the end of the world, but it is a best practice to reduce them as much as possible.

- Every system should have a pressure bi-pass. (All Tanktemp chillers have these included )

- The glycol needs a place to go if the tanks are not calling for cooling.

- Every system needs a pressure regulator. (All Tanktemp chillers have this included)

- You need enough pressure to push the glycol through the system. But, if it travels too fast, it will not pick up the heat. The pressure regulator and the bi-pass can be one-in-the-same.

- Put in a Y-trap strainer. (All Tanktemp chiller 5HP and bigger have this included in the system.)

- Things get into the system and you will want to clean it out.

- Insulation is always the key to efficiency.

- Wrapping your tanks and lines will save you a bundle on your energy bills. About 60% of the BTUs that make it to a tank will escape into the room if the tank is not wrapped; same with the lines.

- Use the right materials

- What to use

- Sch80

- Cool-fit (common)

- PPR Aquatherm

- Pex

- Copper

- ABS

- Niron All-Pro

- Stainless steel

- What to use

- Never use Sch40 PVC

- (The white PVC pipe) This will fail and cause all sorts of problems. It is not rated for glycol.

- Never use Galvanized metal

- It will rust and glycol will ruin it. Also dissimilar metal corrosion will occur. Rust in your glycol system is never good.

- In case you don’t know what that is: https://www.ssina.com/education/corrosion/galvanic-corrosion

- It will rust and glycol will ruin it. Also dissimilar metal corrosion will occur. Rust in your glycol system is never good.

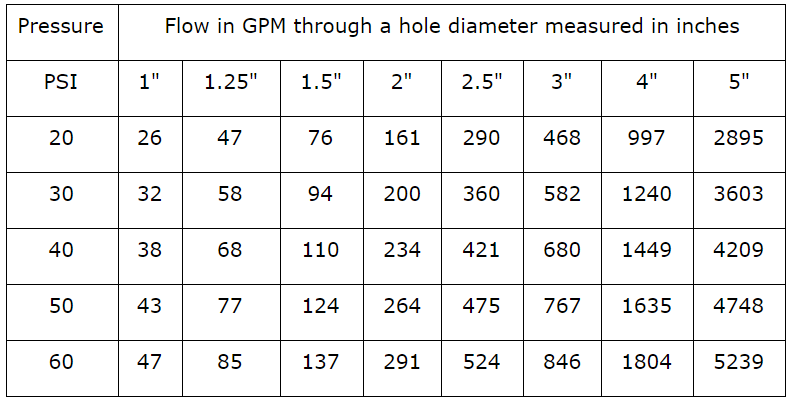

Pipe sizing

We want to make sure we can push enough glycol through the plumbing to feed your tanks, blower coils, and whatever else you hook up to your chiller. Some tanks are rated for 14.6 PSI and others a lot more. Tanktemp has full in-house design and engineering to help you here. Plumb for expansion!

Connections and hoses

Your chiller is all set up, your glycol is set right, your plumbing is done. Now how do you hook up to your tanks?

Our portable units have multi port manifolds that use hydraulic quick disconnect fittings.

Dixon, Parker and Easton are the most common brands and they normally tend to work together. Most groups will have male fittings on all their equipment and tanks and use hoses with double female ends to manage cost. This is our preferred and the most common way we see most groups set up on the glycol side. The quick disconnect fittings are nice as they trap the glycol in the unit, the hose, and the tanks, making it super easy to clean and disconnect things.

Other groups will use male on the feed side and female on the returns, there is no wrong way to do this. It will come down to preference and budget. Some groups request camlock fitting and ball valves. And we have seen systems set up with now release fittings.

Manifolds

We can add a manifold to anything. They come standard on our portable units, but we can add them to our stationary units and we add them to walls in breweries and wineries all the time.

As you add tanks, adding manifolds to key locations will allow you to use your floor space in a more flexible way.

Solenoid controls

Now you want to control the temperature of each tank individually. This can be accomplished with plumbing. Each tank that you want to control separately will need a solenoid valve on the inlet port of the tank to stop the flow of glycol to the tank. A controller, which can be any number of controllers, is attached to the solenoid valve and temperature probe.

Your chiller will need to be set at least 5°F colder than your coldest tank setting. Let's say your desired tank temperature is 36°F, you would plumb and set the controllers on each tank to the desired temperature for that tank, then set the chiller to 31°F. The solenoid valve we open and close to maintain the set point of 36°F by flowing the 31°F glycol through the jacket of the tank until the temperature has cooled back down to 36°F closing the valve.

To illustrate exactly how solenoid valves work, let's assume you have 5 tanks and the chiller is set to 31°F

- Tank 1 is set to 55°F. The solenoid valve would open and close to maintain

- Tank 2 is empty and off. The solenoid would remain closed.

- Tank 3 is set to 30°F. The solenoid valve remains in the open position.

- You will need to lower the set temperature of the chiller to 25°F to achieve this temp.

- Tank 4 is set to 45°F. The solenoid valve would open and close to maintain

- Tank 5 is set to 36°F. The solenoid valve would open and close to maintain

Can I chill a room with a chiller?

Of course you can, by utilizing a blower coil. Blower coils eat BTUs so it is important to make sure that your chiller is big enough to handle the load and plumbing to set up for it. If you are plumbing and thinking you want to cool your space with a blower coil you will need to plumb for that and size the chiller accordingly.

Most of our blower coils are portable, allowing you to use them when and where you want/need them. We can mount them and custom size them to the room and heat load.

The blower coil will not only need to cool the room, but whatever is in the room as well. Every time you open the door it will introduce new air, humidity and heat.

A glycol blower coil is ideal for barrel rooms and fruit storage rooms as they do not pull a lot of humidity out of the room compared to a direct expansion system.

Pumps

Make sure the chiller you got has one… Then make sure it is big enough and rated for the job. A lot of “cheap” chillers either don’t have a pump or they buy the “cheapest” thing they can find. A good pump will make or break your plumbing system.

Other factors with plumbing

- Keep in mind the size of your reservoir in your chiller and the amount of glycol in the lines and tanks. Every time you add a line it will draw the reservoir lower. You will need to refill the reservoir and keep the glycol Brix set correctly.

- When sizing your system keep the reservoir size in mind. The average tank and lines hold about 5 gallons of glycol. If you have 5 tanks that is 25 gallons of glycol coming back to the tank; 8 tanks that is 40 gallons. If your reservoir is only 30 gallons and you return 40 gallons of heated glycol you might bring back more heat than your system can absorb thus increasing your crash times. Also, an undersized reservoir might not be able to absorb the BTUs for the refrigeration fast enough.

- Things like wort crashing and distilling can raise the temperature of the glycol reservoir faster than the refrigeration system can expel the heat. If you have tanks you are trying to maintain at 36°F and run a wort crash, you could now be pumping warm glycol to that cold tank, this can cause issues as your once cold product could now be at 50°F or higher. You might want to look into a tank management plan while doing these steps to prevent this from happening.

- Always keep extra glycol around. The system will lose some no matter what. It can evaporate off, get spilled, extra tanks are added, any number of things can and do happen. Without the easy fix, add more water and that will dilute the mixer and raise the freeze point.

Planning

Interested in learning more about Tanktemp's plumbing planning services? Check out our website here.

Leave a comment

Comments will be approved before showing up.

Also in the Tanktemp Blog

R22 Freon to be banned in 2020

Important changes coming in 2020